So yesterday I bought the last few pieces of track needed to complete the layout. I’ve ended up with a whole bunch of radius pieces that I’m not using – not sure how that happened but I guess I can save them for the next track 🙂

I’ve decided to nail down the track over foam rather than glue it down. Glue is fine for stuff that you never want to change, but I’m not so sure that the layout will stay the same forever. Also, if I find that I’ve made an error in laying out the track as I have, I can change it relatively easily.

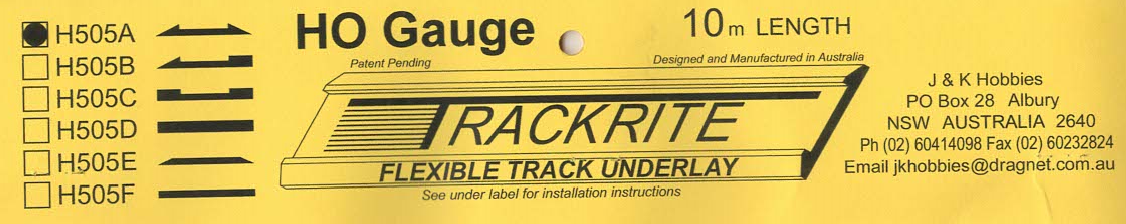

The underlay that I’m using is from Trackrite, an Australian owned company. Trackrite comes in various profiles and I’m using the top one (H505A) which I consider to be the nicest. 10 metres did about half the layout so I’m off to the model shop again today to get another 10m.

To get around the curves, I’m making angular cuts in the foam with a pair of scissors. For a curve of 180° the sum of all the cut angles should add up to 180°. As I’m making roughly 60 cuts per curve, I’m imagining each angular cut at 3° which is working out nicely. I’m really not getting too hung up on the geometry. Smaller radius curves have the cuts closer together than on larger radius curves.