I was about ready to pull the servo from under the table this morning, when I thought I should check the new servo extension cable first – lucky I did because that was the issue. New cable in and it’s all apples again!

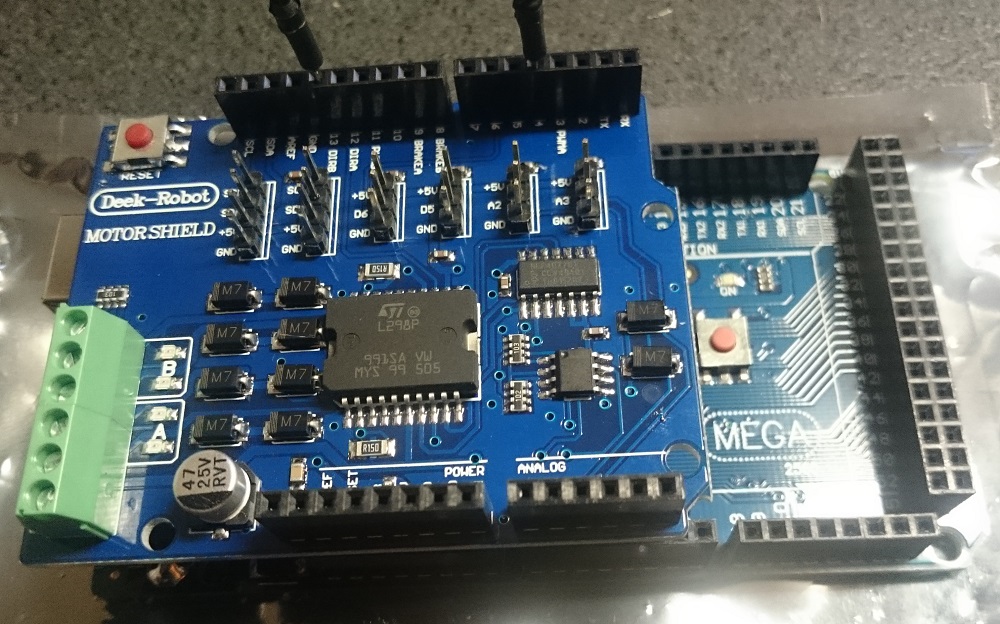

My next task was to cut the voltage connector on the Arduino (Deek-Robot) Motor Shield which ordinarily supplies current to the Arduino so I can use higher voltage on the Motor Shield required by DCC. Then I mounted the Motor Shield on the Arduino and connected pins 4 & 13 as required to generate a DCC signal.

After that, I recompiled the Base Station Master DCC++ code and loaded it into the Arduino’s memory.

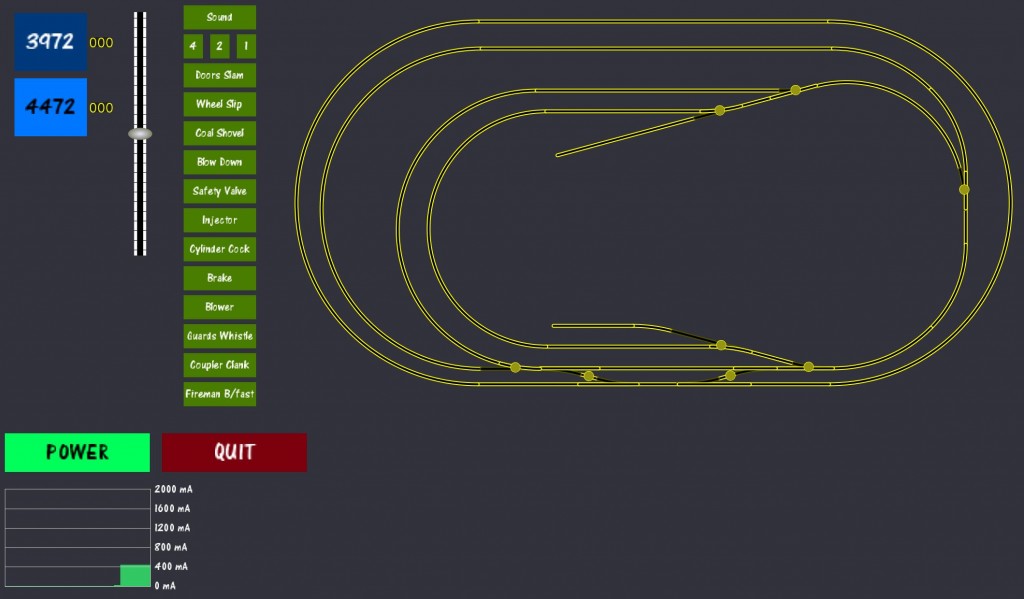

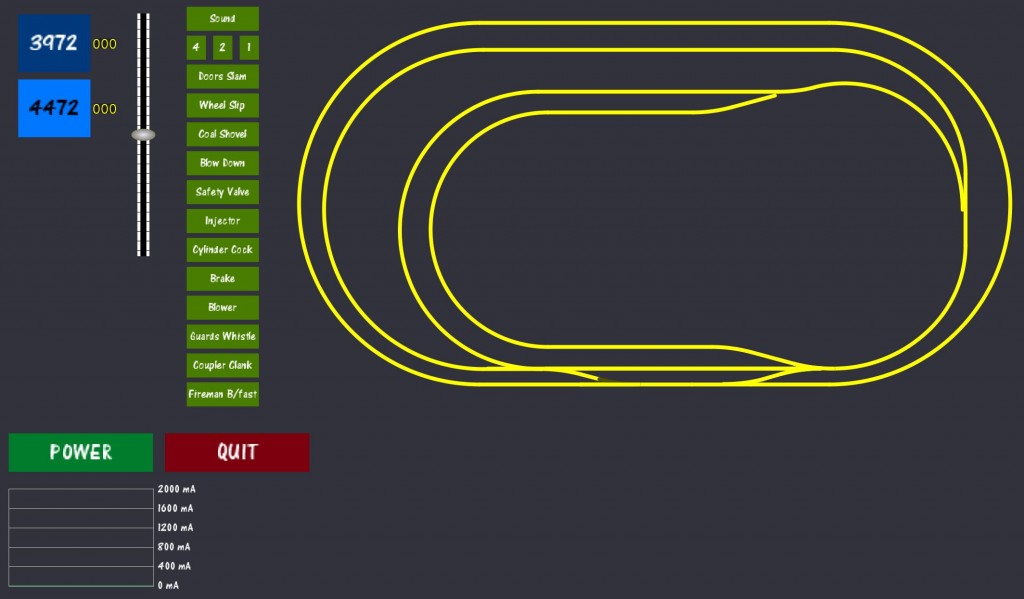

Finally, loading my customised controller layout in Processing, I was able to connect to the Arduino via the USB port. The only trouble I had here was in connecting, but then I re-read the instructions, pressed ‘s’ to bring up the connection options, selected COM3 and voila, the software successfully connected and displayed the results.

Now all I need is a 14V DC power supply…