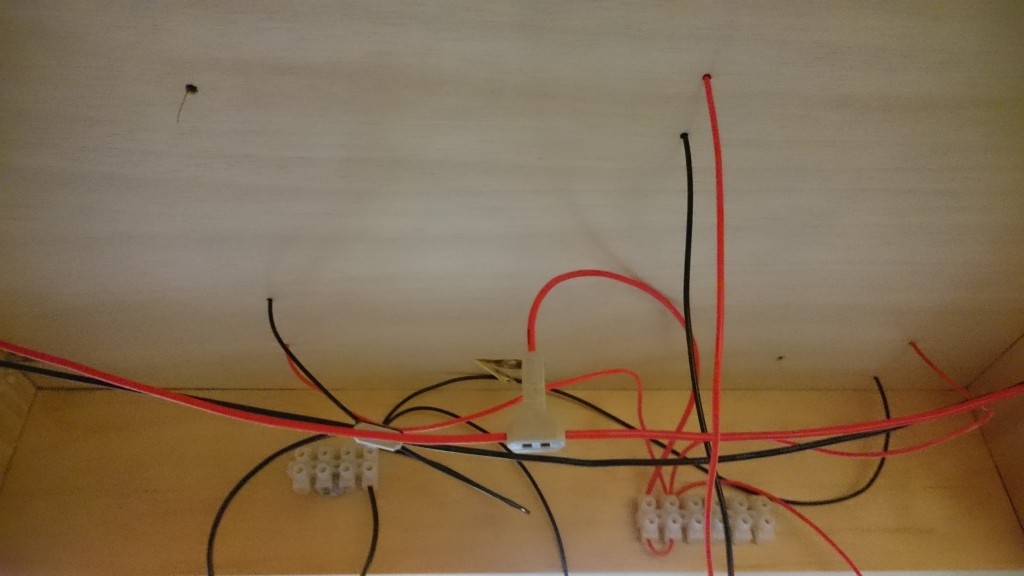

This morning I broke out the soldering iron and resurrected my long disused soldering skills attaching wires to the track. I used T-clips to break into the bus wires I’d strung under the table and connector blocks to take the current to the track. It worked first go and the train went the whole way around … on the outside track.

The other tracks are a bit hit and miss I’m afraid. All those insulator connectors, and I suspect one of the T-clips or connector blocks has not worked as expected as all of the track connected through them remains unpowered.

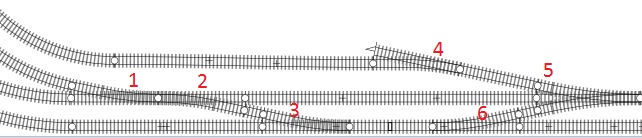

The three way turnout is going to be a problem too until I get power to the frog – which I suspect means I’ll have to wire it up fully. The single turnouts are easy – the frog takes power from the line which is touching.

Edit: The power problem was in a T-Connector but I just hadn’t seated the wire properly. Five minutes with the multi-meter was all it took to narrow it down.